SERVICES

►PRODUCTION

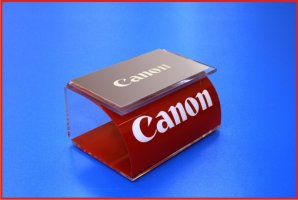

Our company offers various types of products made of organic glass and other materials. Currently, the products of “ANGARS”, Ltd. are produced using modern equipment that encourages competition and development of the product range. The company also invests in new manufacturing machinery. The company’s range of services is based on an individual approach to each client, namely, it manufactures products for specific customer’s needs and desires.

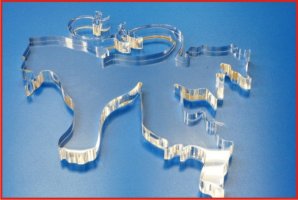

Milling for excising complex shapes of organic glass, acrylic, plastic, wood, plywood and other materials. The milling machine is able to cut and engrave on various materials. The sizes of marks to be engraved are available from 0.5 mm to table dimensions - 3050 x 1520 mm.

►LASER CUTTING

Operational area of the laser machine is 960 x 610 mm. It is also possible to work with long-piece preparations whose width is limited to the size of 960 mm.

Objects can be in various forms with engraving surface in shape of a plane, cylinder or circle.

During the engraving process the top layer of the material is removed by the laser beam and the engraving takes a matt tone. Painted metal surfaces are very good for the laser engraving, as there the product material appears as a result of engraving.

Sizes of objects for engraving are limited according to the surface of the Laser - 960 x 610 mm. It is possible to work with long-piece blocks in width of up to 960 mm.

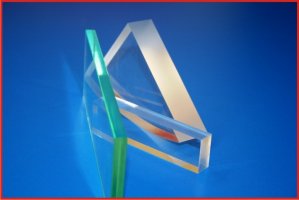

Polishing machines are designed for polishing acrylic with high quality and precision. It is possible to obtain a matt or polished material surface. Polishing machine is equipped with the electronic angle setting; the angular-degree scale varies from -5 ° to 60 °.

The vacuum forming is used in the manufacturing of various plastic products. First of all, a matrix is made on which the vacuum forming takes place. The matrix is made of different types of materials, such as, mdf, aluminum, plywood etc. Costs depend on the manufacturing complexity of the matrix, so the drawings (sketches), the quantities and requirements of the product are required for the estimate. After the matrix has been manufactured the vacuum forming is done, the selected plastic adopts the form of the matrix.

3-coordinate system (x, y, z) allows the milling equipment to do three-dimensional material processing-engraving, milling. It is possible to process the sheet material and other forms of material. The apparatus allows the processing of materials with a maximum height of up to 260mm.

3D forms:

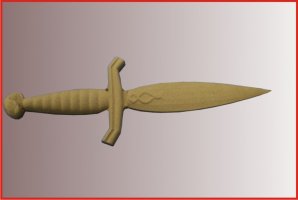

Shapes for thermal vacuum forming are made for various types of signs - indications, advertising and interior design objects.

Foam cutting is done with the company’s CONER ThermoCut thermal plotter, which is run by computer, where a chrome nickel rheostat wire is used that is heated to approximately 8000 C° temperature.

It is possible to make a three-dimensional advertising, various types of signs, decorations, logos, and architectural elements. Using the light and strong materials allow to pursue the most creative and sophisticated projects. Material cutting is done according to the previously given parameters. Due to the profiled wire and use of a rotating table, plotters ThermoCut allow to obtain three-dimensional effects, such as: screws, changing profile blocks for cutting, hollows.

|

|

Plastic repair |

|

|

PHeadlight and sidelight repair |

|

|

Headlight reflector production |

|

|

Exclusive light production |

|

|

Headlight glass coating restoration |

|

|

Radiator repair |

|

|

Solarium glass production lass production costs pdf |

►CUTTING SHAPES FROM THE FOAM PLASTIC AND OTHER MATERIALS

►CUTTING SHAPES FROM THE FOAM PLASTIC AND OTHER MATERIALS